Key Machines for Automating Industry: Industrial Manipulators

Industrial manipulators: Compliance with the need of the day Industrial Manipulator Today industrial manipulators are at work in almost any industry (consider them as capital goods to improve productivity), manipulation equipment has always been present helping people handling heavy materials and manipulating that load easily, quickly but also safely. Such high-tech machines are necessary for transportation, storage, and material handling of heavy-duty items that in the long run help to improve productivity while ensuring a safe working environment. From the going design of security measures to their standard safety protocols, this article provides everything you need to know, explaining all its advanced features such as levelers and ergonomic handling equipment for automation manipulators.

Industrial manipulators have many advantages for people and one of the most important is saving time because they can easily carry heavy loads. These smart tools go a long way in minimising the manual handling risks as well, thereby enhancing workplace safety. In addition, the on-site handling of cargo in a continuous fashion results decreased fatigue and increased employee productivity. Robot arms operate at high speed due to the precision of their motors, which overall reduces how long each job takes, making for a faster and more efficient process on its own.

With the advancement and integration of technologies, like smart controllers and sensors, to improve their performance over time industrial manipulators have come a long way. The smart robots can also be incorporated with manufacturing equipment or human operators without any hassle thus, increasing productivity and ensuring workplace safety at the same time. The enhanced with these features and programs like Novige ATP67 industrial manipulators are making it easier to drive faster, more accurate productivity needs whilst achieving safety standards.

More Features and Safety Stuff

For any work setting, where industrial manipulators are used, safety will always be a priority. Built with a multitude of safety features to maintain exceptional levels of employee wellbeing, such apparatus can significantly reduce the risk factor for manual lifting type incidents changing the nature and scope as well as ensure all tasks are completed within previously defined safe zones. Industrial manipulators, because they help to minimize the chances for injuries on workplace preventions from happenings thus serving as lifesaver.

One of the main advantages that we can highlight for industrial manipulators is their versatility in carrying diverse loads, may they be boxes and cylinders or different grippers, hooks or suction caps. Their versatility allows them to serve in many industries, supporting a broad range of use cases and successfully integrating into various work environments. Today, industrial manipulators are an emerging factor in human's professionality that helps the industry to work more efficient.

Industrial manipulators should be used correctly for making it more productive and safe. Build the machines by following as closely a possible to user manuals so that we achieve correct assembly operations with predetermined load capacity worker Before commissioning, the load capacity of its manipulators must be checked to meet certain requirements. When users adhere to safety guidelines during the operation process then their work will be safe and highly functional.

Techniques of Debugging and Maintenance

Even though industrial manipulators are low maintenance in general, they ' re machines that need frequent control for an effective utilization. This includes tasks such as cleaning and lubricating the rails to ensure smooth operation. Moreover, buying parts straight from the manufacturer ensures that safety regulations and quality standards are met as well making certain the performance of your equipment will have a long life.

The products of company employed in many industries, including home appliances, computer accessories packaging optoelectronics, automobiles and their components Precision gears industry PET preforms industry, household essentials, mobile communication, medical supplies, industrial manipulator industry.

Guangdong Heeexii Robot Technology Co. Ltd. founded in 2019 and is top-notch company that concentrates on R and D manufacturing as well as the sale industrial robots. The company has many employees who have ten years' industrial manipulator.

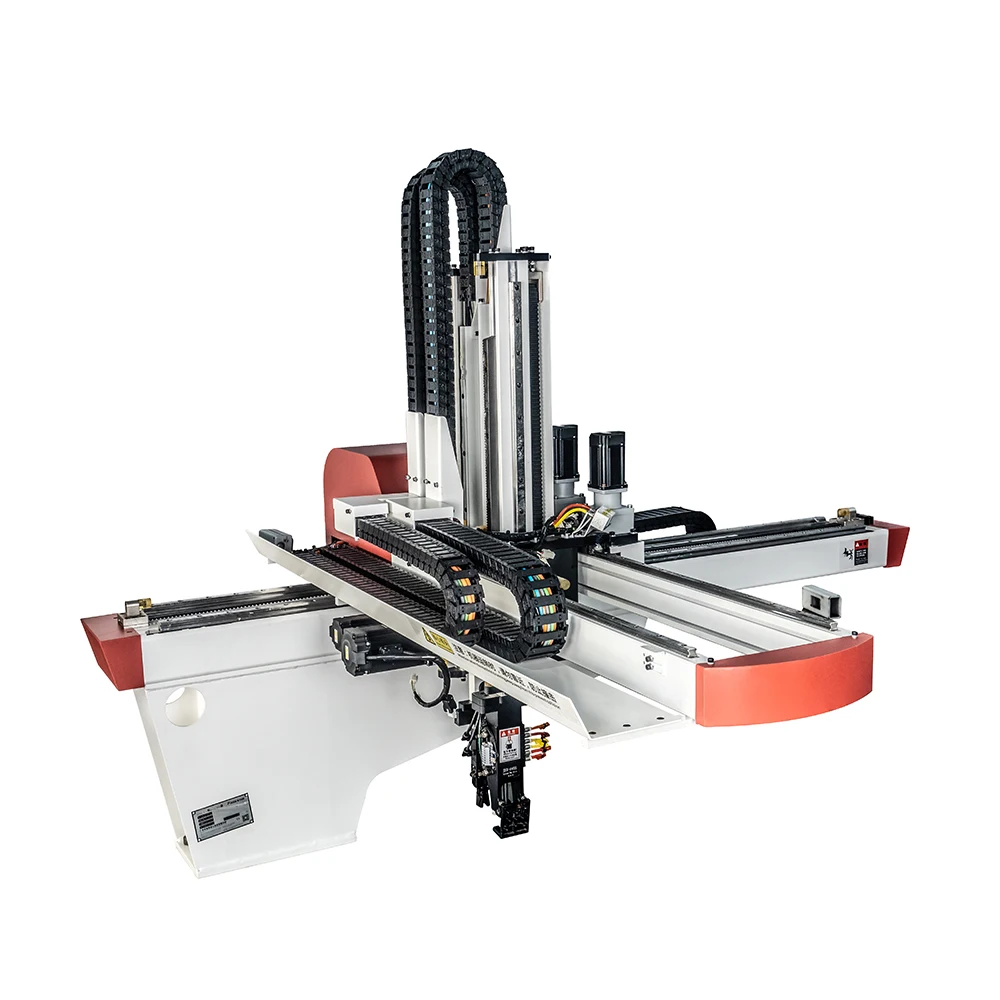

We offer full servo 3 and 5 axis robots that suitable top entry, in addition sprue-pickers and Fanuc 6-axis machines. Our team design an entire automation industrial manipulator includes custom downstream equipment, and even end-of arm-tooling.

Heeexii Robot is characterized by the desire excellence and perseverance innovation, rising attitude of excellence that surpasses oneself; professionalism thanks to focus and because of professionalism. Heeexii Robot will always adhere the principle of superior quality control as well continuous {{keyword}, ensuring the stability reliable users, and contributing to China's innovative manufacturing.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. All Rights Reserved