Benefits of a Pick and Place Robot Arm

A pick and place robotic arm being one of them, is a super cool machine that can revolutionise the way stuff gets manufactured within factories. This is really beneficial in numerous ways for businesses So, let us have a look at why pick and place robotic arm is such an awesome fret really was.

Rapid Fire: Speed is one of the best things about this bad boy robot arm! It operates much faster than people and can work until sprites come home. It won't result in saving energy or a decrease money, but it can crank out tons more things way faster and that is really all businesses need to increase productivity so this makes sense.

Super Accurate: the robotic arm has another cool feature and is extremely precise. It can grab things of all different sorts - big, small, whatever the shape may be and accurately put them exactly where they need to go. This precision prevents unnecessary damage or wastage of the products being transferred.

Consistent as Ever: A robot arm is a master of one - reliable manufacturing that requires precision and routine. This allowed them to create goods with a consistent high level of fidelity and quality every time. This regularity prevents the chance of error and assures best products.

Ensuring Safety- While working on hazardous material safety should be of utmost value in any setting. The robotic arm is the truly unbeatable in this, as they are able to perform those dangerous work which can be hazardous by keeping works out of danger. The robotic arm is used on these dangerous tasks and this help to make sure that the workers are safe from such conditions, since it can do its works done in very bad condition as far expected.

Wicked smart: The robotic arm is poised to redefine what innovation looks like in the manufacturing sphere, as a pinnacle of cutting-edge technology. It is meant for performing types of work that could not be done before within the realm of reasonable, thereby creating inspiring opportunities to businesses. This level of intelligence and adaptability the robotic arm brings to manufacturing is a huge change.

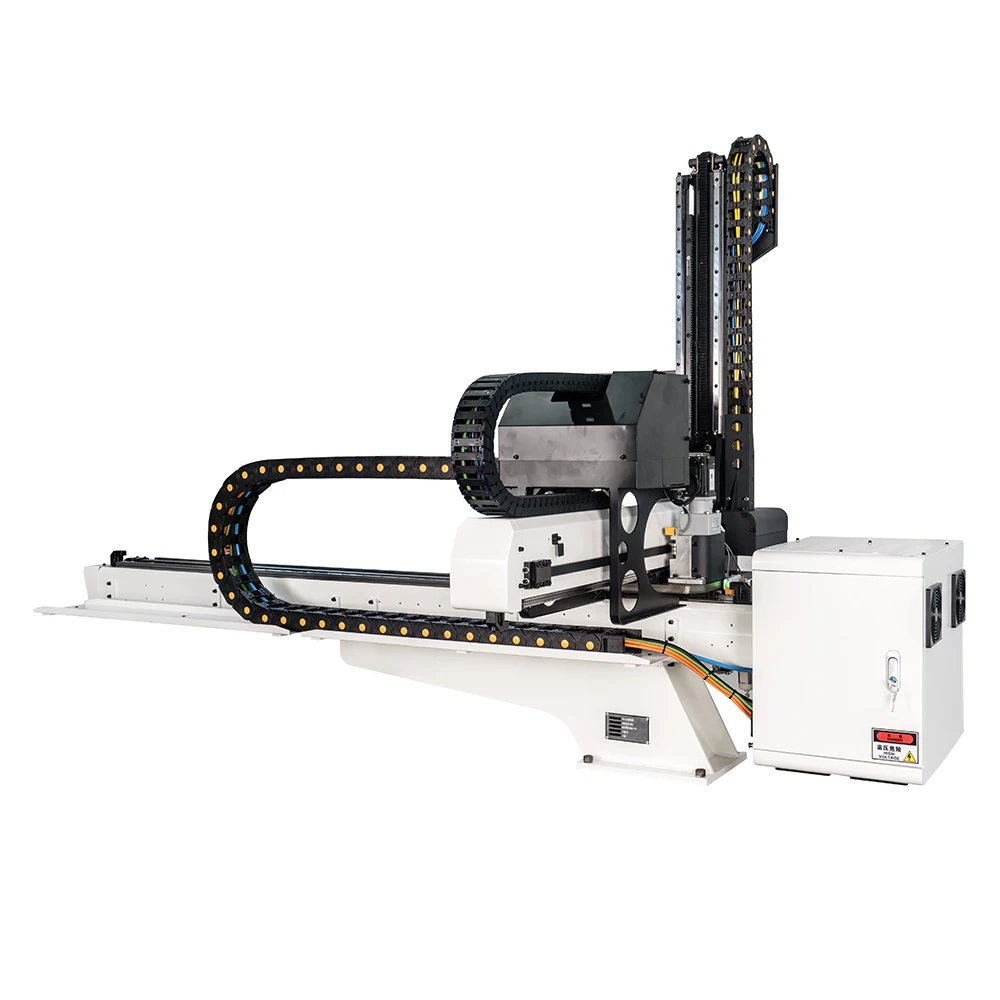

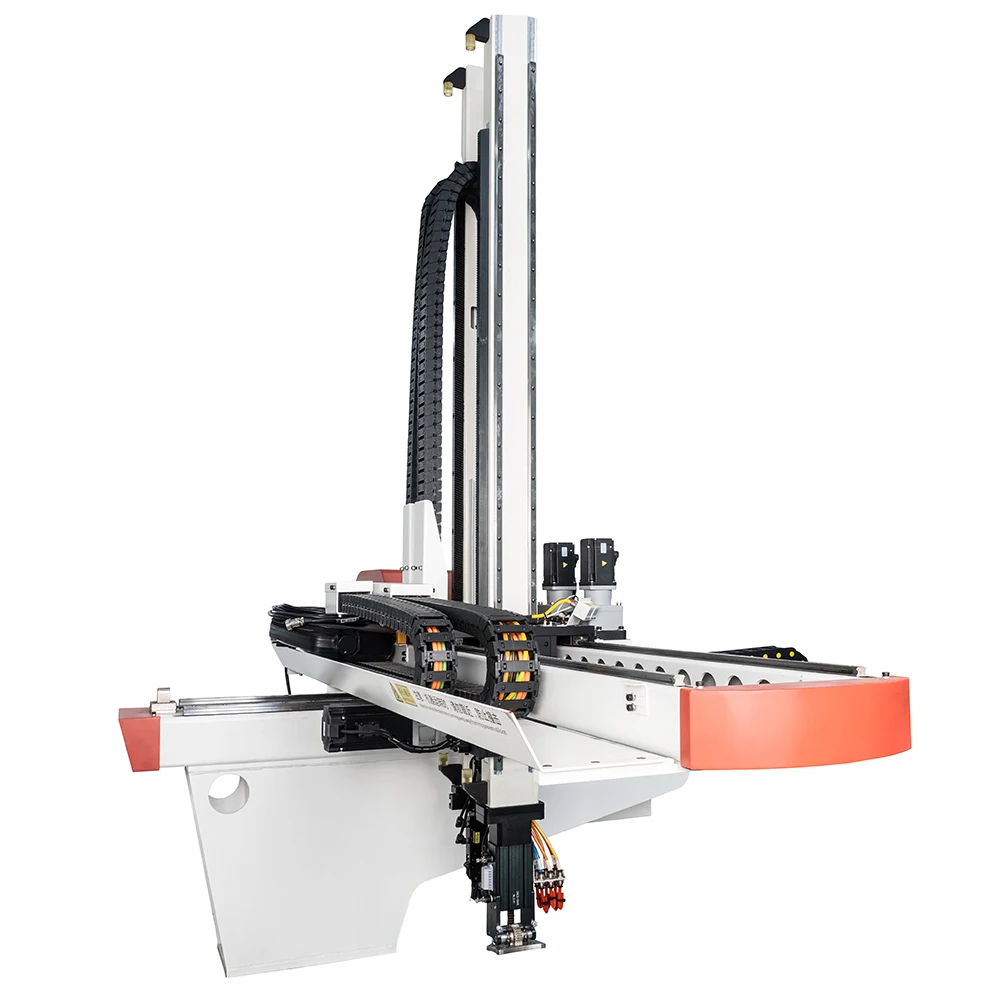

Very different are the applications of the pick and place robotic arm, which makes it such a versatile tool in manufacturing as well. This machine can execute several different kinds of tasks from sorting to moving, stacking to assembling. Used in multiple industries such as automotive, electronics manufacturing for its versatility and efficiency.

Before it is ready to work, the robotic arm must be programmed by a qualified tech in order for it perform particular jobs. Programming then can be done by a controller or specific software, which guides the action of all these robotic arm part. After configured, the machine is able to work on its own, completing what it was designed for without constant monitoring.

A pick and place robotic arm is just a machine after all, thus the service that you will get quite important. They need to know that the product will work and someone from support is there to help if things go wrong. The build quality and low maintenance of a robotic arm is unquestionable, however,in order to maintain that level one must have access to reliable after sales support. Organizations able to keep focus on providing the highest quality service will differentiate themselves among similar competitors and build a loyal customer base.

The quality is the crux of a good pick and place robotic arm. Quality in this case means the degree to which a product operates as intended, producing results with accuracy and consistency over time. Consistency in quality prevents customer return and repair by ensuring that all products are manufactured to meet the expectations of consumers.

Pick and place robotic arms cover a vast range of industries, with each gaining an advantage from the efficiency and accuracy offered by this machine. Whether it is robotics in automotive manufacturing, electronics assembly lines, food processing or healthcare sectors these robotic arms serve the efficiencies and make processes faster. These robots are an incredibly useful tool for sorting, arranging and moving parts from A to B in any kind of industrial process - which improves the overall safety and efficiency.

Heeexii Robot is characterized by pursuit of excellence, spirit perseverance and innovation, a rising attitude of excellence that surpasses oneself; professionalism due to focus; excellence because professionalism. Heeexii Robot will always adhere to the ideals of top-quality {{keyword} control constant improvement, ensuring the stability and reliable users, while making contributions China's smart manufacturing.

The products the company used across wide range of industries, such computers, home appliances packaging for optoelectronics, automobiles their components, precision gears industry, PET preforms industry home essentials, mobile communications medical equipment packaging pick and place robotic arm.

We offer complete pick and place robotic arm 3 and 5 top entry robots' axes such as sprue pickers, sprues, and 6-axis Fanuc. Our team will design entire automation cell including end-of-arm tooling, custom downstream equipment, different equipment molders can use. The core technology R and D team adheres to independent research and development method has accumulated a range of patents and intellectual property rights.

Guangdong Heeexii Robot Technology Co., Ltd. established 2019, is a new pick and place robotic arm which focuses R and D and manufacturing, and sales industrial injection molding robots. The company has dozens of employees ten years industry experience.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. All Rights Reserved