One of the indispensible tools that allow industrial sector in automation handling and material is Pneumatic arms. Powered by air, they merge human ingenuity with machine accuracy - and bring a new definition to punk rock. They are highly essential within a number of industries, increasing output levels to aiding in safety methods and ergonomic practises. The flexible and quick-pick arms of pneumatic manipulator give them superlative benefits in different areas for ultimate good betterment which reduces environmental effect at the same time.

Pneumatic manipulator arms are all about making workflows of use more efficient and comfortable for staff. Unlike the manual method, these systems are able to lift heavy loads easily and move them from one place to another. It is time-consuming and resource-intensive for workers to perform the same task, also tends to provide more physical relief. The robotic arms lift the additional weight of manual labour so that, in taking on strenuous workload - and thereby bolstering ergonomics at the workplace - they help stave off fatigue and musculoskeletal disorders among 2 workers ()and contribute to an overall higher morale from within as well. The results are there will be higher productivity in the workforce.

Pneumatic manipulator arms are strong choices for any industrial environment due to the increased safety of removing heavy lifting tasks by workers. The implements come with load protection systems and emergency stop buttons as out of the box safety features to ensure workers, as well as goods stay securely in place even when operating under unforeseen conditions. This enhances safety at the workplace by allowing for automation of dangerous or cumbersome lifting tasks, hence reducing accidents. There are less safety concerns, which is to say that workers will not be injured as often when hazards do present themselves; and of course, if nobody ever gets hurt on the work floor then guess what happens - productivity goes up because there's no lag time in production (i. e., downtimes).

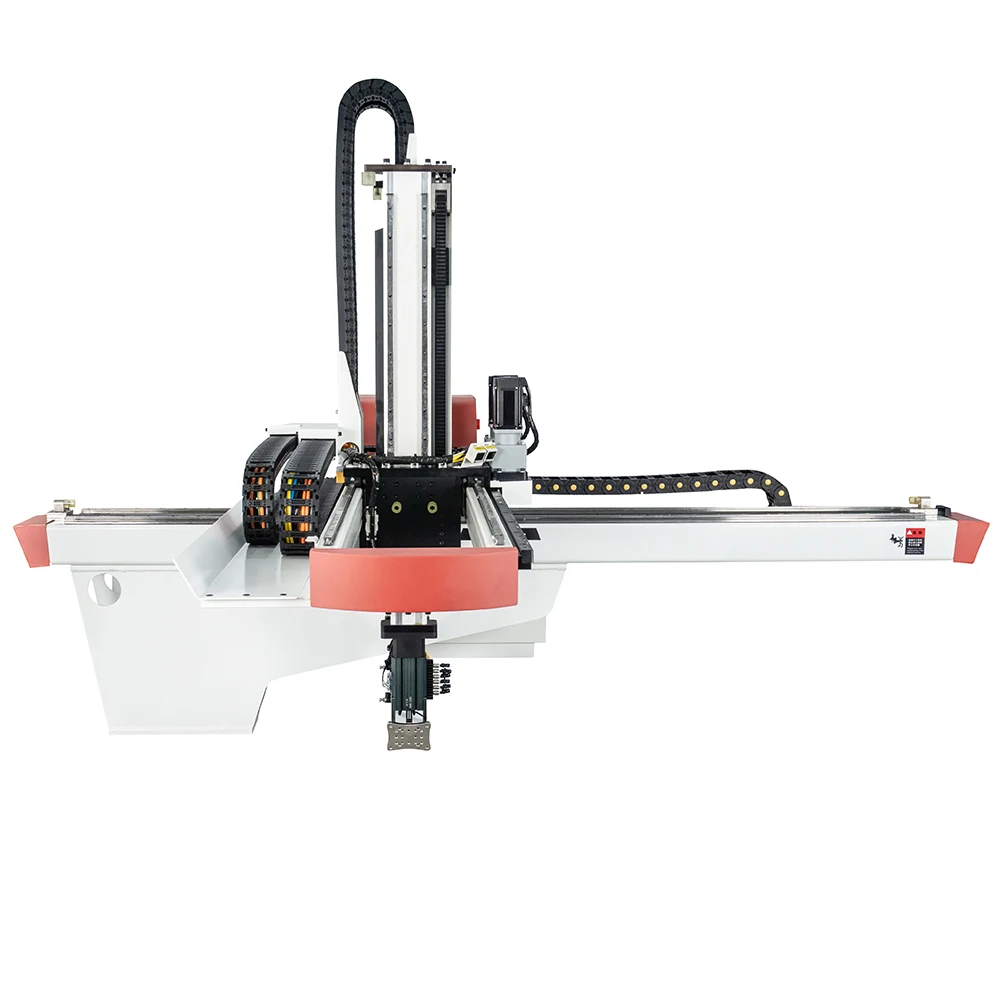

Perhaps the most astounding thing about pneumatic manipulator arms is their adaptability. The arms are easy to use and application specific ranging from automotive assembly lines, food processing plants or pharmaceutical labs lifting sensitive items. Apart from transporting large loads, they are widely used in various fields because of their ability to transport both highly delicate components and heavy parts. These arms have customizable end-effectors and a lifting capacity that can be easily adjusted to suit various shapes, sizes, weights of materials as well as a variety other such NK cell products which advanced in design effectiveness streamline both line processes simultaneously enabling widespread implementation within production lines. This simplicity to integrate into existing machinery further adds to their flexibility, rendering them a perfect fit in almost all industrial formations.

Using pneumatic manipulator arms eliminates most workplace injuries setting in due to material handling. The use of these arms reduces insurance liability, workers comp claims (who wants a sore back) and increases productivity by automating what was once the most dangerous part in any factory/warehouse type setting. Not only does this protects employee health but it also benefits productivity with non-stop workflows and more potential of running 7/24. Simply put, pneusonic arms are a force multiplier for better quality and greater quantity of production.

The products of company are utilized various industries, including computers, home appliances packaging pneumatic manipulator arm, automobiles their components manufacturing precision gears, PET preforms home essentials, mobile communications medical supplies, packaging industry.

We offer complete servo 3 5 top entry robots with pneumatic manipulator arm as well as sprue pickers and 6-axis Fanuc. Our team develop an entire automation cell comprising end-of-arm-tooling, customized downstream equipment, and different equipment molders use. The primary technology R and D team is committed the independently run research and development process and has accumulated a range of patents intellectual property rights.

Guangdong Heeexii Robot Technology Co. Ltd. was established in 2019 and a top-notch company that concentrates on R and D and manufacturing as well as sales pneumatic manipulator arm robots. The company a staff of employees more than 10 years' experience in industry.

Heeexii Robot is characterized by the quest for excellence well as the determination keep going and innovation, a rising attitude and a desire to excel beyond oneself. professionalism due to focus; excellence due professionalism. Heeexii Robot will always adhere the {{keyword} of first-class quality control constant improvement, ensuring the stability and reliable of users as well as contributing China's intelligent manufacturing.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. All Rights Reserved