Efficiency And Saving Cost,These are the two things every Modern manufacturing company looking to do in their process. The good news the solution is getting a lot smarter and it comes in the shape of robotic arms for injection molding machines. Control arms of robotics, that is what has taken over the world when it comes to manufacturing automated injection molding with such precise and fast acting accuracy no human can match all while costing companies less in production by diminishing waste.

The world of robotics in the field of injection molding technologies is undergoing rapid evolution, and the latest developments are highly impressive. The newest robotic arms come with other smart capabilities: they are connected to an AI and built out of machine learning. With automatic material volume prediction for each mold, up to 20X faster defect identification and validation processes help ensure high-quality reinforcements are produced every single time they're used - so not only can you learn from use by continually improving performance. The sensors and cameras on these robots are monitoring the production process round-the-clock to troubleshoot & detect errors.

This is how we will build the products on even factory floor level,robatic arms have been implemented in every place of manufacturing so this is future. It is this adaptability that puts cobots in a strong position to take on more sophisticated jobs such as:Completed Part StackInsert high precision and repeatability insert [Column Stacker][bin picking operation Made using some of the most advanced sensing and vision systems, these vengeance bots are designed to air out any moving portions correctly for effective efficiency against other machines on a factory floor/or an assembly line. Robotic automation in manufacturing assists companies to alleviate bottlenecks, expedite cycle times and ultimately stage up their production capacity meet the augmented demand.

Selecting the right robotic arm for an injection molder can have a huge impact on a company's bottom line. Robot Automation helps a business to replace labor sysyems and this reduces the cost of it which inturn boosts production. Robotic machines can work 24 hours a day producing products in the systematic format without errors and no mistakes due to coordination problems which will take production level high i.e. such high that it holds less waste, where this little bit of waste is nothing than money as dividends leading development for their firms.

To this end, it is no better and faster than injection molding robotic arms to achieve unsurpassed accuracy rates of production. Robots are far superior in producing parts with zero variation from the required specifications, as they can continue to operate at 100% without feeling tired or make a mistake. In addition, robots are fast in their work and so they will always effective products at less time. All this precision and speed mean that manufacturers will generate parts of the stipulated quality in record time, which leads to improved profitability & customer satisfaction.

In short, robotic arms for injection molding machines are a game changer in the modern age of manufacturing. These revolutionary machines are designed to work with maximum efficiency and have better product quality at less cost. Macro : By using Robotics, a company can increase its production scale and improve their market level. Meaning that even if you just got to the point of considering a robot arm on your injection molding machine it could yield an amazing amount of opportunities and efficiencies in how you ran things!

Heeexii {{keyword} is characterized by the quest for excellence well as determination to keep going with a soaring attitude, ingenuity transcends oneself; professionalism through focus; excellence due to professionalism. Heeexii Robot always adhere to the ideals of top-quality quality control and constant improvement, ensuring the stability and reliable users, as well contributing China's smart manufacturing.

Guangdong Heeexii Robot Technology Co., Ltd. established 2019 is a new star enterprise focuses on R and D and robot arm for injection molding machine sales of industrial injection molding robots. The company many workers over ten years of industry experience.

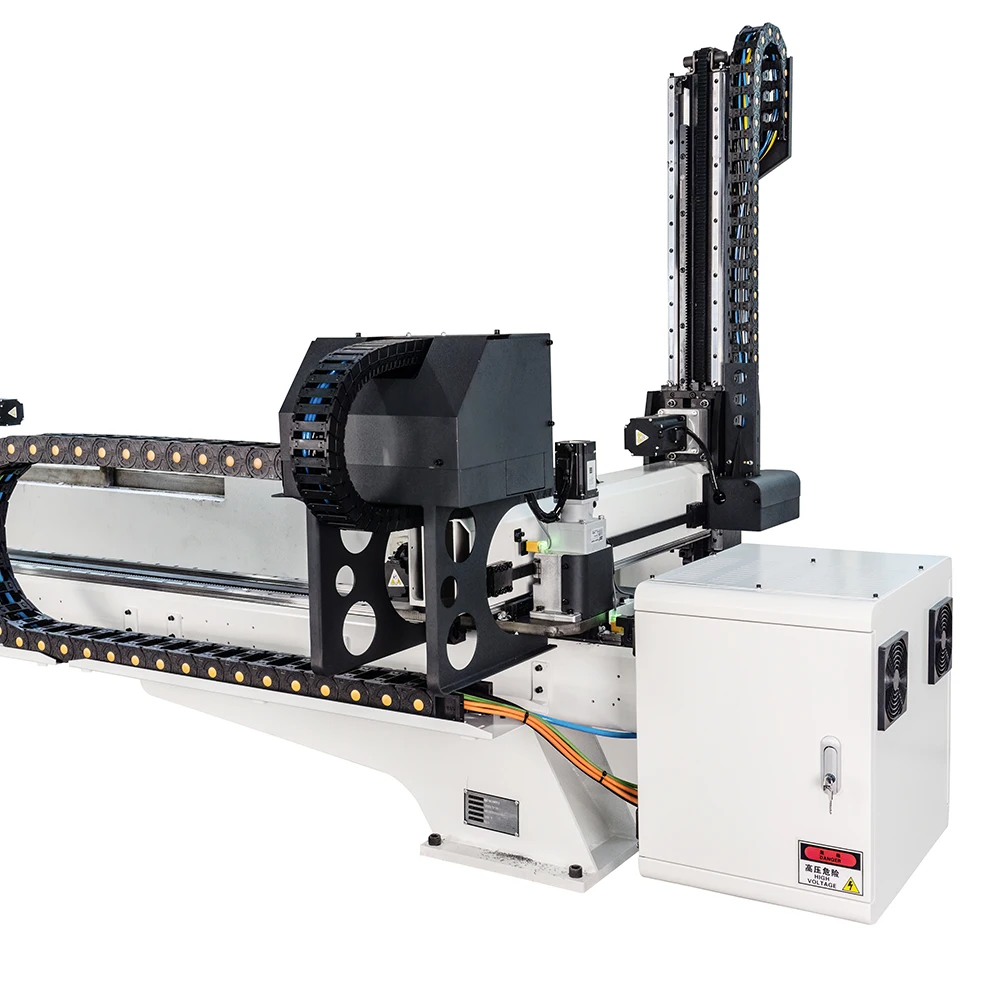

We offer servo servo full 3 5 axis machines for top entry as well sprue-pickers and Fanuc machines six axes. Our team will robot arm for injection molding machine automation system is complete, including end-of-arm-tooling and custom downstream equipment and types of equipment molders could use. The main technology R and D team follows the independent research and development process and has secured a variety of intellectual property rights and patents.

The products of company are used across a wide range of industries, as home appliances, computer accessories packaging optoelectronics, automobiles and components Precision gears industry PET preforms, home essentials, mobile communications robot arm for injection molding machine supplies packaging industry.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. All Rights Reserved