Robots are a special type of machine used by humans to accomplish something quicker and with least effort. It is a helper that makes it easy for you to do chores accurately and with ease. That is what robots are capable of. They are ideal at performing tasks that require dexterity and accuracy. Another type of robot that most individuals are interested in is a robotic arm. The Application of robot arms enables extremely sensitive and precise movements of objects. We will observe in this article how the use of information can turn these robot arms intelligent and thus greatly assist them in such activities.

Robotic arms transform the manner in which we produce.

Factories make things, like cars and toys and computers. They are centers of much activity and serious business from morning until evening. Factory robots have transformed the workforce such that work is quicker and more efficient, and things thus can be done more skillfully and effectively. Robot arms are also used greatly because they can be precise in performing tasks. Robotic arms, for instance, can grasp small pieces and place them where they need to go on a machine. Something that is probably not everyone's forte because it requires a whole lot of care and precision. Robots are just handy in a way to ensure accurate positioning, a key to the successful production of good products.

Giving Robotic Arms a Slightly Greater Input of Information

Information is the input we apply to make decisions. Information teaches us to read on how things operate and where we can add to them so they are improved. Factories accumulate a lot of process information in order to advance their process and make their work efficient. The same information turns out to be extremely useful in these robotic arms because it helps companies make the work better. For instance, a company would be interested to know how much time one robotic arm takes to accomplish a job. They can then use this information to adjust the manner in which the arm operates, making it work faster or more efficiently. Equipping companies to get their manufacturing robotic arms to work smarter, not harder, and in a time and cost-effective way, by interpreting and analyzing this information.

How Smart Technology Makes Robotic Arms Smarter

Smart technology robotic arm price is machine intelligence. This means that machines can think and decide on their own without always relying on assistance. With special devices like sensors and cameras, robotic arms can be intelligent in their own right. So, a manipulator arm, for example, has a sensor that tells it that you have completed picking up a piece. This sensor will enable the arm to decide when it should stop grooving and when it should deposit the piece where it should go on the machine. The smart technology is allowing firms to achieve new productivity and efficiency. Companies thus get some time savings with intelligent robotic hands and some savings on costs which is crucial in any industry.

Smart Robotic Arms to Get Work Done Faster

Efficiency robotic arm grabber is a large term that means to do something quickly and on a large scale. Robotic arms sometimes are able to do things quicker and better than humans, a fact which allows manufacturers to produce more goods within a shorter span of time. Another term which can be applied here is data-driven technology, meaning the use of information to facilitate smart decision-making for machines. With this type of technology, companies may make the robotic arms do even better. A business may need search results to instruct a robotic arm to do as hoped. This makes the arm accomplish its work faster and more efficiently, allowing the entire operation to flow smoothly.

The problem is that you are practically on the tree.

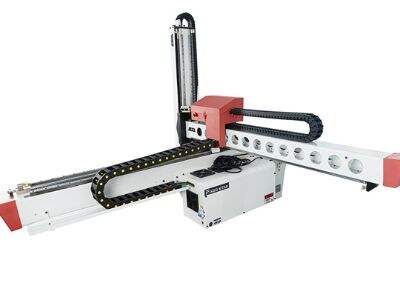

Analytics is a technical term for the gathering and examination of data utilized to make sensible decisions. Firms can make their 3 axis gantry operations efficient and streamlined with the help of analytics for robotic arms. For instance, a firm may use analytics to figure out the most efficient way for a robot arm hand to execute a task. They can learn how to reduce the time it takes to complete the task and avoid errors by learning from this data. Robot arm analysis helps companies streamline their factories and make sure that their stakeholders get the job done successfully.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

LV

LV

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

IS

IS

LA

LA

MN

MN

KK

KK