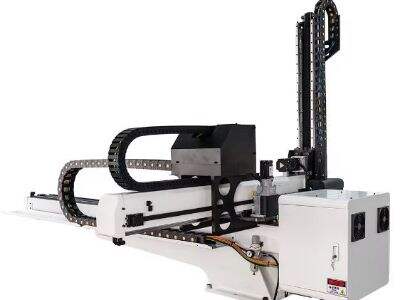

Injection Molding Robots: Making Manufacturing Safe, Faster, and Better

As much as one might think of Robots, the first thing that comes to mind may be the cool toys or just tales as in the transformers. But still thing come further than just sci-fi and being toys robots. There are other auxiliary equipment like injection molding robots which have been incorporated in manufacture processes to manufacture better quality products. In the next section of, we will see that these robotic manipulator are bringing about a change in how products are made., we will address issues like: Benefit; Advance; Development; Implementation; How to employ; Performance; Standard; Utilization; and Application.

Advantages: Faster Production, Higher Precision, Lower Costs

Firstly, let me tell you about the benefits of employing injection molding robots in manufacture by HEEEXii. First of all it increases production in an incredibly fast speed due to the involvement of robots. They do not get tired or get weary, as such these servers run on a continuum, throughout the year, or rather, the entire year round. Compared to workers, 6 axes robot are far superior and are capable of performing certain jobs within a couple of seconds while it may takes human worker few minutes or even hours.

Another advantage of robots is the degree of precision, much higher than their capabilities to set a high degree of formation of the desired shapes and configurations. They also do not make mistakes since their control systems are computerized, meaning they will perform just as they did previously in the future, thus unlikely to make a mistake like a human worker. It also assists in controlling for defects, which lowers the amounts of waste and the costs that enterprises have to incur in the process.

Innovation: Advancements in Robotics

Automated systems are not something new or groundbreaking, as they have been existing since the 1950s. However, the prospects that are stimulating are in the real sense the progress made in the unfolding Robotics technology. Advanced and advanced robotic arms for manufacturing applications and solutions are being invented and tuned to need different kinds of industries such as manufacturing industries. With the science of machine learning, sensors and artificial intelligence, these robots can now repeat what used to be routine assignment at much larger rates and efficiency. It is capable of ‘teaching’ the product new tricks without the need for explicit programming.

Safety: Keeping Workers Safe

Other benefit of implementing the use of robots in the injection molding techniques is that it leads to increased safety. Used in the manufacturing industries, it avoids occasions where workers have to carry out dangerous machines with an option of causing accidents. Robot itself is made with so many precautions such as remote sensors and other apparatus that reduce chances of having an accident.

Use: Adopting Robots in Industries

But first let us take a look at the history of the mechanically constructed workforce and its evolution from a luxury item to a necessity. Companies are turn to robot to replace labor in injection molding and other processes. However, this not only increases the speed of work but also eliminates the need for extra personnel, which in turn saves on overhead expenses. As a result, due to robots being able to operate continuously and with no rest, the pace of production can be increased with a reduction in the proportion of labor.

How to Use: Integrating Robots Into Business Operations

Installation of robots needs the operational technicians who can work with robots and advanced installation techniques. These technicians ought to possess comprehensive knowledge of the injection molding cycle as well as the comprehensive programming and maintenance challenges that go with robotic systems. Some organizations may decide to employ in-house training initiatives while others hire personnel from institutions or service providers who have prior experience in the use of robotic systems.

Service: Ensuring Optimal Performance

Automated systems will also need frequent attention to keep them running efficiently as they may include robotics. As suggested earlier, servicing entails a set of technicians who must have undergone through training to address a robotic system. Maintaining a robotic system involves actions like repairing eroded walls, installing various program upgrades and carrying out safety measures. These service are important because they help in maintaining the robotic systems at their optimum in terms of performance ; and not to develop faults.

Quality: Delivering Top-Quality Products

Last of all, injection molding robots are employed to ensure that ultimate part quality is achieved. It is possible to note that robots as efficient tools can provide production of high quality and accurately formulated and non-defective goods without interruption. This results in the enhanced customer satisfaction, interpreted in terms of long-term revenue creation to firms.

Application: Industries That Benefit From Injection Molding Robots

Precision injection molding robots are utilized in all the different industries including automobile industry, medical equipment industry, toys, and electronics. It is therefore appropriate to state that any company that may need to produce large volumes of products can appropriately benefit from the injection molding robots. For instance, the manufacture of auto parts employ use of robots in production of auto parts including bumper covers, and interior parts among others. In the medical world, robots are employed in production of parts for implantation, surgical tools, etc.

Table of Contents

- Advantages: Faster Production, Higher Precision, Lower Costs

- Innovation: Advancements in Robotics

- Safety: Keeping Workers Safe

- Use: Adopting Robots in Industries

- How to Use: Integrating Robots Into Business Operations

- Service: Ensuring Optimal Performance

- Quality: Delivering Top-Quality Products

- Application: Industries That Benefit From Injection Molding Robots

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

LV

LV

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

IS

IS

LA

LA

MN

MN

KK

KK