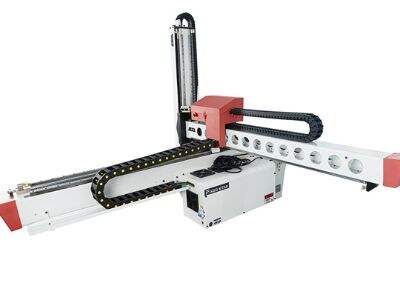

Today we are going to learn how injection robots change the production way in the factories. It is a special type of robot that uses specially designed end-effectors called 3-axis manipulators. The end-effectors make the robots get to work more efficiently than ever before, and here at Heeexii, we are really proud to be a part of it with this great, cool tech to bring efficiency in manufacturing.

What Are Injection Robots?

Injection robots are specialized machinery used in producing a wide range of products. They can produce anything from toys to auto parts. For these robots to work, hot liquid material would be fed into a mold. From there, the material at the bottom fills the mold, cools down, and hardens. This is repeated, again and again, to produce the required number of products. This allows factories to crank out lots of items over a brief period of time.

Issues with Older Injection Robots

The older robots are not very effective and are defective. These injection robot only have two motions: the motion that travels from up and down and sideways as well as forward and backward. With such motion, it is unable to access every portion of the mold. It is in the areas it is unable to reach, then production will be prolonged. It also translates to extended lead time for production and makes it an ineffective process.

Improved Robots Performing Injection Using Better Equipment

Enter the new 3-axis manipulators. Injection robots have to be able to move in at least three dimensions: up and down, side to side, and forward and backward, which necessitates the use of specialized tools. This means it can have easy access to every corner of the mold. This added flexibility allows the robots to do a better job by greatly improving the manufacturing pipeline in terms of efficiency and speed. A Close Look at the Greatness of 3-Axis Manipulators

For an plastic injection robot, there are a lot of advantages in using 3-axis manipulators. For one thing, these devices let the robots work much more quickly and precisely than ever before. to say less time in making things; that saves cost and gives factories the ability to build more products in less time.

3. axis manipulators have the advantage of one simple 3. axis manipulator being able to work with many different kinds of molds. This means that the manufacturers can make all kinds of different products. They can experiment with different shapes and designs, which can help sell more pieces and make more profit. This agility is crucial in the dynamic market of today.

How New Tools Improves Injection Robots

New 3-axis manipulators have transformed the way those injection molding robots function. They have never been more precise and accurate than ever. Improvement allows the manufacturer to produce better quality products. For products done right, customers are happier with those products, making it more likely that they return and buy again. These innovations are important for the ultimate satisfaction of customers, vital for every business.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

LV

LV

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

IS

IS

LA

LA

MN

MN

KK

KK