Robotics arms’ ability to intimately replicate human arms to perform very complex tasks is quite amazing. It finds application in a wide array of fields from manufacturing, healthcare, defense and many more. The fact that 4DoF robotic arm is one of the commonly used kind reveals how much it is well suited as compared with all other robotic arms due to versatility and easy programmable parametrically. In this endeavor, this article seeks to describe what a 4-degree of freedom robotic arm entails and how it’s implemented and also its algorithm to program it, general design factors that should not be ignored when contemplating implementing it, and other possible areas of any industry. What A 4DOF Robotic Arm Really Is and How it Works A 4-degree of freedom robotic arm is such a kind that has four joints just in the same way you use your own hand. Specifically, these joints can be used for either up and down movements or side to side or back/forward in the wrist and along their twisting axis. These are primarily 4 major joints of a robot arm that makes its duties more accurate which include base or shoulder joint, elbow joint,wrist joint which comprises of gripper for holding objects. felt each of the moves its direction in wh position where all of these joints is going for everything to be controlled and coordinated effectively.. The gripper is designed in a manner that it only moves in the x-direction so that it will only be responsible for taking or placing objects.

It is the programming that serves as a dictum for robotic arms, and each joint has different commands to move it according to its assigned task. In large, heavy-duty applications the robotic arms are programmed through computer numerical control (CNC), which in cases of other medium-come-light duty jobs [however some industrial light robots might too], can involve micro-controlling that utilizes software but not as complex. CNC programming tells the arm how to move, and employs sensors and feedback systems that enable it make real time adjustments when its environment is different than expected...microcontrollers are really great at just this sort of thing because they effectively sense by looking at these same types of data in only microseconds.

A major benefit of the equipment is that it can be used in an extensive variety of applications. Ideal Candidate for 4 Degree-of-Freedom Robot Arm Industrial - used in repetitive tasks such as painting, welding works and material handling which can be performed by the robotic arms (in manufacturing) Surgical processes or handing over to people with disabilities are some medical application of them. But for some reason I think robotic arms has too many flaws. It has lesser Degree of freedoms so, its mobility is only rotational but robotic arm moves more DoFs and same time Easy programming where every joints can move linearly as well rotationally simultaneously in case the issues with high complex operations. Secondly, the arms are not very dexterous so doing more fine level of work is difficult.

Programming The 4 DOF arm requires a good hands in Python or Java as the programming language. Mainly It contains task of writing code for each joint to complete functions that will operate in programming phaseAnd there are two types of programming methods used in these robotic arms which firstly is Teach pendant prograammng and second one off-line porgramming. This is the kind of programming where you have to move, by hand, a robot arm and record all positions which will then be translated into code. This can be a slow and rather technical process if run correctly though. Off-line programming simulates the movement of robotic hands in 3D modeling software.

When designing a 4-dof robotic arm kit, ensure to check the constraints and conditions that will let it be operated with ease. Speed, Accuracy, Load carrying capacity and the flexibility of workspace requirements are some very crucial aspects in an industry. Choosing the right hardware and using them means you perform proper due diligence with your arm to get the task done.

The use of 4-DOF robotic arms have impacted areas like medical and military circuit since its advent. And intricate medical arms that have allowed for surgeries on a scale so small and delicate no human could perform them themselves. They are utilized not only in the military, but also on explosives and hazardous material for safer handling as well. And these robotic arms help in other areas as well, where the human entry is not possible besides search and rescues.

Therefore, 4-DoF Robotic arms have changed the game in enhancing task performance and accuracy from different sectors as well. Robotic arms are versatile and may perform work that need to human hands, however not continuously. Due to their simplicity, they are the number-one choice for many robotic enthusiasts and industry professionals alike but still somewhat limited. It is equally intriguing to ponder the future potentials of robotic arms by means of technology.

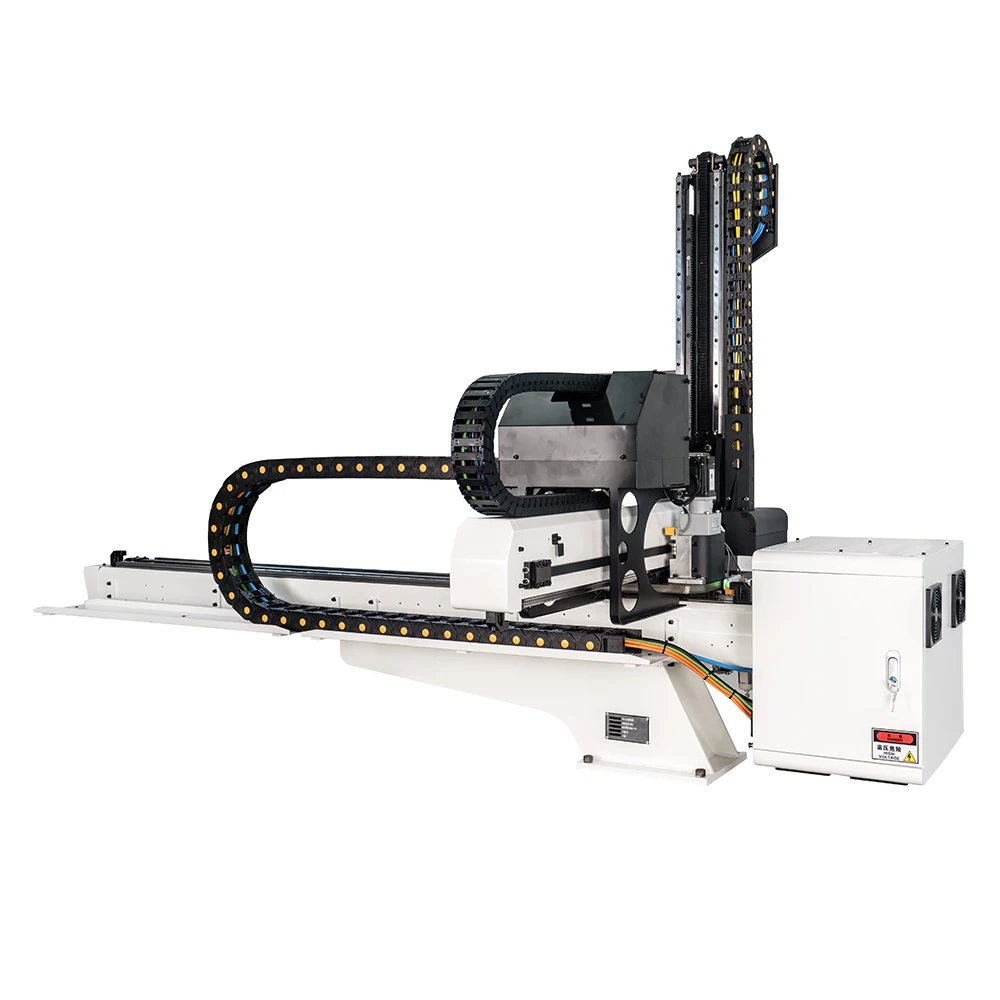

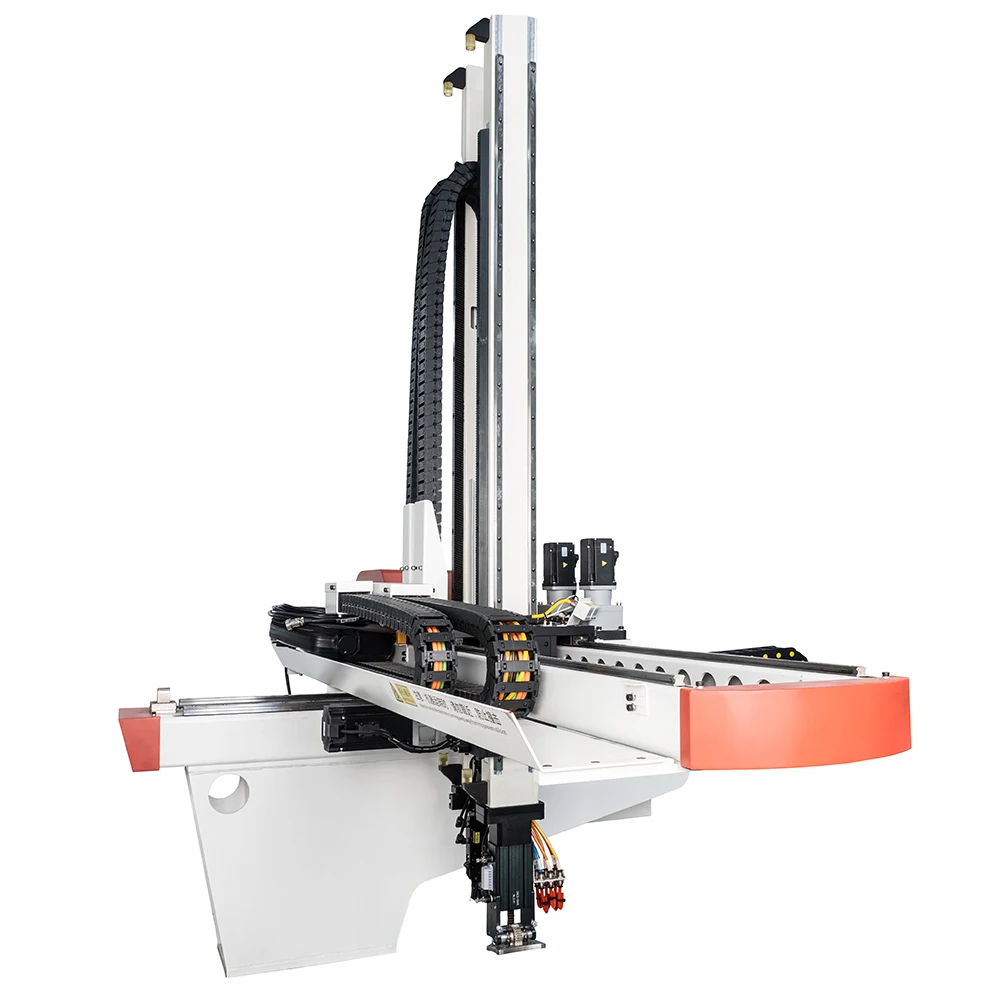

Guangdong Heeexii Robot Technology Co., Ltd. established the year 2019 is a brand-new enterprise focusing on R and D, manufacturing and selling industrial 4 degree of freedom robotic arm molding robots. The company employs dozens of employees more than 10 years of experience in industry.

The products of the company widely used industries such computers, home appliances optoelectronics cosmetic packaging cars and their parts metal processing equipment, precision equipment industry, PET preform industry, consumer electronics, mobile communication industry, medical supply 4 degree of freedom robotic arm packaging industry.

We have servos full servos 3 and 5 axis robots for top 4 degree of freedom robotic arm in addition sprue-pickers and Fanuc 6-axis machines. Our team create an entire automation cell includes custom downstream equipment end-of arm-tooling.

A Heeexii fő értékei közé tartozik a kiválóságra való törekvés a {{keyword}. Felkarolják azt a képességet is, hogy a kereteken kívül gondolkodjanak, a növekedéshez való hozzáállást, hogy a legjobbak legyenek, túlmutatva önmagukon, a professzionalizmusnak megfelelő elszántságot és a professzionalizmusnak köszönhető legmagasabb minőséget. A Heeexii Robot mindig ragaszkodik az első osztályú minőség-ellenőrzés folyamatos fejlesztésének szelleméhez, stabil és megbízható felhasználókat biztosítva, miközben hozzájárul a kínai feldolgozóiparhoz.

Copyright © Guangdong Heeexii Robot Technology Co., Ltd. Minden jog fenntartva