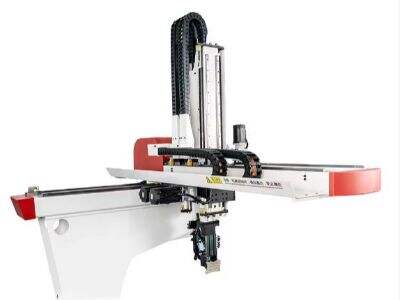

Injection Molding Robots – The Smart Way to Boost Production Effectiveness

Have you grown out of constantly having to grab or extend and shape what is possibly plastics every day? Would you like it if you could wish to have a call that could reduce the amount of time, energy, and money needed in the process? Well, if this is the case, then perhaps the injection molding robot we’ve discussed above might interest you personally.

Advantages of Injection Molding Robots:

IMRs have a lot of advantages over other types of mass production include; They are truly fast, efficient, and cheaper compared to the others; and that is why it is good for manufactures and producers. In addition, they are able to perform several assignments at one time, which helps reduce cost and time, Here, their capacity is in multicasting.

Innovation:

The Injection Molding Robots by HEEEXii use advanced technological tools together with the pc software to be developed in a way that your production line grinds to a halt. As being a outcome, you can guaranteed that both of your items are going to be of the best quality as much as possible with little if any waste of time and mistake.

Safety:

As mentioned above, injection molding robots are designed for safe use, and you, your employees, and everything near them, will always be protected from every danger that might occur. They encompass various safety precautions for instance movement detectors and safety signals to reduce event of accidents and cases of injury.

How exactly to Make Use Of Injection Molding Robots:

Working with Injection Molding Robots is very easy since it has been designed in a very intuitive manner. First of all, the injection molding robots will undoubtedly appear as machines which will perform certain functions regarding the thermal processing of plastics, including heating, melting, shaping, etc. Secondly, you will have to supply the materials which are natural the robot’s hoppers and then you push the start button. At last, the robot shall take care of the rest – it must accomplish all tasks promptly and effectively.

Service:

Injection Molding Robots are the type of equipment that were intended to have long life cycle and reliability. But, in general, with any questions or concerns in the whole case, there are services of qualified suppliers available to help you. This will put them in a position to diagnose the constant issues that are leading to a break-down, fix or replace any faulty section and ensure your injection molding robots for sale is back up and running.

Application:

These injection molding robots are used in a number of industries, including the automobile, medical, aerospace, etc., within numerous organizations. They can make a ranges is wide of structures like gears, valves and often various other complicated parts are formed.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

LV

LV

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

IS

IS

LA

LA

MN

MN

KK

KK