Robot Molding - Security Comes First

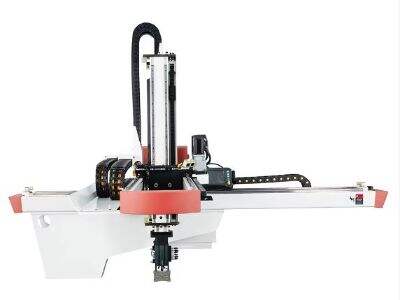

They make robotics an important element of the production in modern, holding numerous advantages in concerns to cost and accuracy simplifies. In this case, injection molding robots, particularly, have a role is winning the molding process a stream line more fine quality and consistency, and lower cycle time. However, safety should be a consideration when it comes to the operations performed by these injections molding robots just like any other equipments. First, let’s consider some guidelines for increased safety of robotic manipulators in injection molds and further operation during the service as well as the changes that make the robot an integral part of the manufacturing process.

Advantages of Injection Molding Robots

Hand molded robotics is still increasing popular among manufacturers because injection molding robots by HEEEXii are offered to give numerous advantageous consequences to whoever buys them. It can do complex and repetitive work, as well as jobs that are physically strenuous and would tend to be menial and risky for humans. In addition, the use of injection molding robots enhances production time reduction through the removal of hand operations to create lean, manufacturing processes that are cost effective.

Innovation in Injection Molding Robots

Of all the industries that have gone through a sea change in the past several years, the injection molding industry could well be one of the most so, and robots have in fact been instrumental in this change. One example serves as a good illustration of this concept of innovative work and that is in the manufacturing of collaborative robots. These are designed to co-exist with human beings in operating the injection molding hence enhancing the reliability and reliability of these processes. Effective for operations of various types of tasks and easy to program, collaborative robotics has become increasingly attractive to small and a medium-sizes enterprises and large companies alike.

Security in the Use of Injection Molding Robots

Devices that are evolving in the process of manufacturing have in one way or the other incorporated security. Firstly, operators are required to pay strict attention on safety is proper each time they are using injection molding robots for sale. First, and this is rather important, lighting in the ongoing, must be consulted, providing for proper lighting together with other safety measures. Before handling any material is plastic make sure the robot is in safe mode acting as its security buttons.

Before driving the robot, alway ensure that the system is correct addition, the robot is into the right mode that is. Besides, always ensure the robot is locked correctly you should definitely and always stick to the instructions recommendations in handling the robot to avoid accidents which are often associated with their handling.

Utilizing Injection Molding Robots

The individual procedures involved in the operating of an injection molding robot are easy. The end-effector, most often known as the gripper of the robot, needs to be precisely placed to ensure a tight hold of the mildew. In the process, positioning is done carefully of robot’s arm to ensure that the mildew is picked up correctly and placed in the right area. Once the robot has obtained a firm hold on the mould, it transfers it to somewhere that is passable for starting the injection moulding operation. Last, after a product is done and the process is over, it removes the product out of the mold and puts it in a suitable location/area.

Injection Molding Robot Service and Quality

Since injection moulding robots are like any other machines, it is important that they are serviced now and then to allow the best performance. It is relevant to establish service schedules or quality checks which are relevant for common machines to ensure that the robots are in good condition is working that they produce quality products. Though during service the injection moulding robots is in constant use, its security features have to be carefully examined to avoid any given dangers which are potential. Also, the gripper should be cleaned frequently to allow aseptic control since any contamination that gets into the manufacturing environment may affect the process. Electric circuits and wiring should be checked as well and when they develop faults, they should be correct as soon as possible to avoid breakdowns.

Applications of Injection Molding Robots

Bottles making through injection molding is important in several sectors such as the health sector, manufacturing of automobiles, aerospace industries and construction among others. These are normally a critical application into the production of goods such as that of bottles caps, containers and components of automobiles among others. It is also likely that they can build robots with molds that are higher in precision than what one can do themselves. Thus, it is easy to identify the advantages of such advanced level and accurate molds, inclusive the following: the molds have been used in making medical instruments, medical devices, and prosthetic devices in the medical industry.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

LV

LV

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

IS

IS

LA

LA

MN

MN

KK

KK