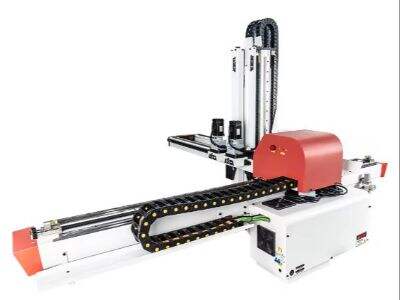

Boosting Competitiveness with Injection Molding Robots

In the current world market, every organization aims at lower production costs as this is a way of cutting down the production period. High-speed injection molding robots are another type of innovation that is highly solution is practical automating difficult and repetitive tasks. They will include points such as the benefits of injecting molding robots, the security measures incorporated in them, how they function, quality of product being produced using these robots, and the various uses of the various injecting molding robots.

Advantages of Injection Molding Robots

It is admitted that injection molding robots by HEEEXii provide many beneficial attributes to the manufacturing companies Some of them are, first of all, injection molding robot are economical, The overall efficiency rate is enhanced and production yield is increased. Reduzing the amount of human companies that means not only decrease of the work costs but also let to exclude a large number of employees’ injuries. Devices can perhaps work 24/7 which may be more comfortable to increase a manufacturing’s total and decrease manufacturing lead times.

Besides, when it comes to the manufacturing process, injection molding robots offer better precision and accuracy than traditional manufacturing, which contributes to a minimum range of product defects of the in a lesser range product defects commonly associated with production in the industry. These benefits directly contribute in increasing the bottom line and the business that are operational must be competitive.

Innovation in Injection Molding Robots

The latest developments in technology have really made the injection molding robots to be more reliable as well as efficient as compared to the previous versions. Newer pc software and several complicated & special algorithms let the injection molding robots control even this many manufacturing is complicated such as hot runners along with multi-cavity molds. They are also equipped with sophisticated sensors and systems that act as surveillance cameras, detecting any variation on the process and making the necessary changes. These boast make it possible to realize, consistency while at the same time raising production is high quality.

Safety Features of Injection Molding Robots

Further, the injection molding robots are known to be safe for workers besides benefitting the organization by being efficient and more economical than the traditional systems. They are fitted with sophisticated packing analyzers that keep track of who or what enters their work environment, which may include objects, animals, and even people. The robot immediately halts all activities and comes up with a message to the device operator. This feature reduces the likelihood of a worker sustaining an injury within the working environment and, thus, improves the safety of the entire manufacturing process.

How to Use Injection Molding Robots

It is important to note though that despite the fact that injection molding robots are as highly autonomous as they can be, their utilization entails some deft. The step that precedes ahead is to choose the right robot in regard to the specificity of the identified company’s requirements, for example, the size of the molding machine, the type of components to be manufactured, and the number of cavities in the mold.

These are very powerful machines and they are designed with a variety of options regarding accessories and extensions to fit different molds. They also discovered that, once the robot has been set up and physically installed in the production line, it requires programming to accomplish the required operations. The operator types out certain commands into the automated robot instruction unit for example informing the particular robot to pick up certain ‘ready to mold’ parts, shifting some parts from one area to the other, cutting and polishing this product is final.

Effect on Product Quality

As for the most part, injection molding robots are expected to play the role of one of the key components towards attaining the manufacturing of quality. This reduces errors that might have resulted from guesswork and labor is manual, these are known to cause errors. This automation also helps in ensuring that all the components that are produced are standard as that of the main product as well as the consistency is well checked at all the time. With injection molding robots for sale, the risk of having to recall the product at a very expensive cost, or lose the trust of customers due to poor quality products is also reduced.

Applications of Injection Molding Robots

Automated injection molding robots may be utilized for the range is wide of in various sectors that include auto making, medicals manufacturing, and aerospace industries. They could be used to make a number of products that greatly include small and complex parts and conversely large ones. Some other applications include:

1. Electrical connectors

2. Medical implants

3. Containers and lids

4. Automotive components

5. Consumer goods

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

LV

LV

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

IS

IS

LA

LA

MN

MN

KK

KK